pneumatic crusher selection

screen crusher selection criteria

Media Selection and Installation— The Fast Track to Screening ... Jun 13, 2014 ... "Wear on the screen media can be significant, impacting not only longevity .... of maybe making changes at the crusher settings, chutes or feeders. .... this is how it always has been done is no longer a valid selection criteria. Chat Now

Buy Carb Crusher Selection Box | MYPROTEIN™

THE Carb Crusher bars are the ultimate highprotein snack — with their triple layers and topped with crunchy crispies — they're a supernutritious treat for sweettooth snackers everywhere. So, indulge in a world of bittersweet Dark Chocolate Sea Salt, fruity Strawberry Cheesecake, and smooth Caramel Nut with our Carb Crusher Selection ...

Electric Aluminum

Vanitek 16 oz Aluminum Bottle Opener | Heavy Duty Large Metal Wall Mounted Soda Beer Smasher – EcoFrie. Sold by FastOnlineDirect. __unknown__ Can Ram Aluminum design 10 cans Fast Recycling Beer Soda. Sold by bitshopus an eBay Marketplace seller.

selection of coal crushers

The primary crusher selection is the key to the success of the mining, quarry or ... for any crusher, so that the selection of suitable primary crusher is a multicriteria ... It has been China's cement, building materials, quarry crusher coal and...

Pneumatic Sanding Machine

Nov 29, 2005 · A pneumatic sanding machine includes a body, a pneumatic motor assembly mounted in the body and a control valve detachably mounted in the body to change the path of compressed air that actuates the sa. Chat With Sales; Pneumatic vs. Electric Sanders The Wood Whisperer. Pneumatic vs. Electric Sanders Article .

PNEUMATIC

"PNEUMATIC " ABSTRACT Problem Definition: (Recycling Of Metal Cans) Nowadays all the beverages, cold drinks, oil, perfumes etc are packed in metal cans. After use these cans are disposed off, they take a lot of space and as it is, this increases pollution.

DESIGN AND FABRICATION OF PNEUMATIC JACK FOR .

of mercury, nearly 30 inches high in an ordinary barometer. Any gas can be used in pneumatic system but air is the mostly used system now a days. SELECTION OF PNEUMATICS: Mechanization is broadly defined as the replacement of manual effort by mechanical power. .

CHAPTER 5: Pneumatic and hydraulic systems | Hydraulics ...

Typical pneumatic circuit. Figure 51 includes a pictorial representation and a schematic drawing of a typical pneumatic circuit. It also has a pictorial and schematic representation of a typical compressor installation to drive the circuit (and other pneumatic machines). Seldom, if ever, is the compressor part of a pneumatic schematic.

Basics of Pneumatics and Pneumatic Systems – IspatGuru

Nov 14, 2015· Pneumatic cylinders, rotary actuators and air motors provide the force and movement for the most of pneumatic systems, for holding, moving, forming, and processing of materials. To operate and control these actuators, other pneumatic components are needed such as air service units for the preparation of the compressed air and valves for the control of the pressure, flow and direction of .

chicago pneumatic grinder

Chicago Pneumatic CP875 1/4" Die Grinder | HP | 22,500 ... The CP875 Right Angle Die Grinder by Chicago Pneumatic is a general purpose tool designed for light to medium maintenance applications in nonproduction environments. Use the CP875 in conjuntion with your favorite sanding disc or carbide burr to achieve your surface preparation goals.

DESIGN OF A RECYCLE BIN TIN

A mechanical tin is basically one of the most aid able machines. It helps to reduce the pollute environment of this world. Thus helps create a better place to live in. apart from that, this tin can actually be the future mode of recycles apart from the recycle bins.

CHAPTER 5: Pneumatic and hydraulic systems | Hydraulics ...

Pneumatic systems. Air motors are one of the most costly components to operate. It takes approximately one horsepower to compress 4 cfm of atmospheric air to 100 psi. A 1hp air motor can take up to 60 cfm to operate, so the 1hp air motor requires (60/4) or 15 compressor horsepower when it .

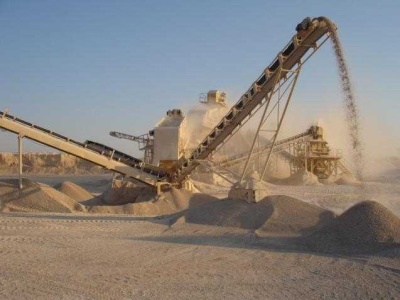

MASTER YOUR OUTPUT CRUSHER SELECTION QUICK .

CRUSHER SELECTION QUICK GUIDE PLAN YOUR OUTPUT You can only choose the right crusher if you know exactly what you want to achieve. overall profitability depends on the balance between fractions and fines.

pneumatic grinder

Sioux Tools Pneumatic Grinders . Sioux Tools Grinders. Sioux Tools Pneumatic Grinders. Sioux Tools provides a wide selection of grinders for your application. Available in models with speed range up to 25,000 rpm to help you get the job done quickly and efficiently. Contact Supplier

The Crusher | Cabernet Sauvignon

The Crusher Cabernet Sauvignon is sprinkled with aromatics of blackberry, treeripened fig, toasted cedar and hints of mocha. A truly expressive wine, also showing hints of violet, rosemary and coconut. Bold, dark cherry and blackberry compote laced with rich, dark chocolate covered coffee bean.

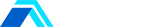

Rock Crushing Equipment 911Metallurgist

In a smaller installation, the crushing plant should be designed with the minimum number of required equipment items. Usually a crushing plant which can process 300 to 500 metric tons per operating day will consist of a single primary crusher, a single screen, a single secondary cone crusher, and associated conveyor belts.

Cone Wear Parts Selection Guide CCP Casting

You are here: Home / Blog / Industry News / Cone Wear Parts Selection Guide The engineers at CCP are highly experienced in the aggregate field, so you know that when you order Wear Parts from us for your crushing machine, it will be of the highest quality and made to fit perfectly.

Latest Posts

- كسارة مخروطية مستخدمة في العراق

- معدات تكسير الحجر الجيري الجزائر

- تقرير مشروع لكسارة خام الحديد

- تهتز آلة الشاشة أوتار براديش

- ثمن الاحجار المعدنية القابلة للتصدير في الجزائر

- سحق الزرنيخ

- الجرانيت الشركة المصنعة للكسارة المتنقلة الأولية

- الشركة المصنعة لآلة التفجير الرمال

- غسالة للحصى

- المملكة العربية السعودية كسارة الحجر الصغيرة لفة كسارة الحجر المنتج

- كسارة فكية متنقلة صغيرة الصين

- مصنع تصنيع مسحوق الباريت

- كسارة الاسمنت في مصنع كسارة رايبور

- سعر معدات كسارة الحجارة في الجابون

- تقنيات جديدة في تكلفة الكسارة

- diamond mining crusher feldspar

- zenith first in coal production in india

- penjaga weroller untuk pabrik batubara loesche

- iron ore crusher equipment mining crusher company

- concrete equipment

- x jaw crusher produce

- granite aggregate beneficiation equipment

- medium scale dolomite hammer mill for sale

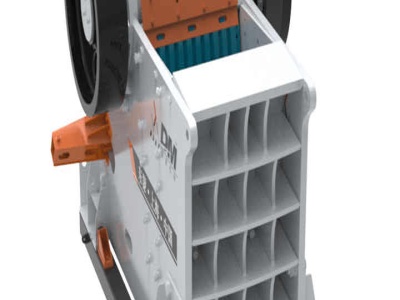

- suppliers of conveyor belts in kenya

- reclamation and rehabilitation of area polluted by iron ore mines

- hook crusher raymond

- build vibrating screen operation

- jaw hammer crusher prices hammer crusher drawing

- crushers used in lting

- jaw crusher gtgtjaw crusher guangdong