making coke from coal

Making charcoal. Solid Fuels: Coal, Coke, Charcoal, Wood ...

I really wanna make mass quantities of charcoal. I have a large 100 gallon tank I'm thinking of making a retort. I want something I can capture the gas and feed it into a burn chamber. I have seen someone's avatar on here that is exactly what I'm looking to build. I will search and see if I can find who it is.

Coal carbonisation coke making : ALS

Using pilotscale coke ovens, benchscale coke ovens and a range of coke test apparatus, ALS can determine the coke quality of your coal. With extensive testing and research experience, ALS can provide guidance on the value in use of a particular coke relative to a range of globally traded coals.

Coking | Article about Coking by The Free Dictionary

coking[′kok·iŋ] (chemical engineering) Destructive distillation of coal to make coke A process for thermally converting the heavy residual bottoms of crude oil entirely to lowerboiling petroleum products and byproduct petroleum coke. Coking an industrial method of processing natural fuels (mainly pit coal) by heating to 950°–1050°C in the ...

China steel mills caught on the hop by North Korea coal ...

While North Korea accounts for only a small portion of China's total coal imports, it is the main foreign supplier of highquality thermal coal, called anthracite, which is used to make coke, a ...

Metallurgical Coal (Coke) James Conner

Coal is used to make coke for the iron and steel industry, foundries, and other industries. The presence of large domestic deposits of coking coal, or metallurgical coal, played an important role in the development of the iron and steel industry.

Coke Production US EPA

Coke Production General Metallurgical coke is produced by the destructive distillation of coal in coke ovens. Prepared coal is heated in an oxygenfree atmosphere (–coked–) until most volatile components in the coal are removed. The material remaining is a carbon mass called coke.

Coal Coke Team CoFH

Coal coke is a material obtained by processing coal in a redstone furnace with pyrolytic conversion installed. It can be used as fuel, or as an ingredient to produce steel. Obtaining Redstone Furnace with Pyrolytic Conversion

Selection of Coal for inclusion in Coal Blend in Coke Making

Sep 26, 2015· The procedure described above for the selection of coal for inclusion in coal blend in coke making explains that there is a necessity to achieve a balance between the requirements of throughput, high coke quality, battery life, cost efficiency, and overall economics with an assurance of a consistent supply of the coals.

What's so good about coke made from coal | Belleville News ...

Aug 23, 2016· Coke, a kind of purified coal, was an essential ingredient in turning the iron and steel industry into a powerhouse after the 1880s. The demand for coke .

Steelmaking: The Coke Oven ByProduct Plant

The coke oven byproduct plant is an integral part of the byproduct cokemaking process. In the process of converting coal into coke using the byproduct coke oven, the volatile matter in the coal is vaporized and driven off. This volatile matter leaves the coke oven chambers as hot, raw coke oven gas. After leaving the

Coke Making Process

Coal is crushed and blended prior to being charged in a coke oven. A larry car charges the individual oven with the blended coal. In the coke oven, the coal is heated to 1,800°F for up to 18 hours. During that time, the volatiles of the coal are driven into the offgas and a pure carbon form called "coke.

How to make coke? Problem Solving I Forge Iron

Mar 04, 2009· I heat my shop with coal, and find hot coke in my coal stove most mornings when I come in for work. I'm tempted to just use my stove to make coke for the forge, but wondered if anyone has messed around with making coke in any quantity, tips for doing so, etc. Don't bother googling "how to make coke", unless you want to learn how to make drugs.

Coke or Coal for a forge? : Blacksmith reddit

So I want to make a troughshaped forge that will get air flow pumped in through the bottom. My goal will be to make cutlery, chests, tools, etc. and maybe try my hand at making medieval weapons when I've become skilled enough. I was wondering if I should use coke or coal as a fuel source, and what the pros/cons for each are?

What is clean coal technology? | HowStuffWorks

Coal is a fossil fuel composed primarily of carbons and hydrocarbons. Its ingredients help make plastics, tar and coal derivative, a solidified carbon called coke, melts iron ore and reduces it to create most coal 92 percent of the supply goes into power production [source: Energy Information Administration]. ...

How to Turn Carbon Into Graphite | Sciencing

Apr 24, 2017· Create coke from coal. Coal is a form of carbon. Using an airless furnace, cook coal until all of the gasses and liquids have been removed. This includes water, coal gas and coal tar. The temperature used can reach as high as 3,630 degrees, so the energy and equipment required are typically only used by industrial producers of graphite.

Coke making process and its environmental impacts: Blogger

Apr 14, 2008· Coke making process and its environmental impacts: Coke is a solid carbon fuel and carbon source used to melt and reduce iron ore. Coke and coke byproducts, including coke oven gas, are produced by the pyrolysis (heating in the absence of air) of suitable grades of coal.

Latest Posts

- أفضل مصنع لآلات كسارة الحجارة في مصر

- شركة سحق في السودان

- تصميم حزام ناقل خام

- آلات الرطب طحن الصغيرة

- كسارة الحجر سعر النباتات والتفاصيل

- كيف آلة غربلة الرمل الدوارة

- كيفية بناء الذهب محطة غسيل جاف

- عملية غسل الرقصة

- يمكن أن الهباء الجوي كسارة وينيبيغ

- المصنعين مطحنة الحجر المملكة العربية السعودية

- آلة فصل المعادن

- تدمير الصناعة الكيميائية

- آلات الحجر حصاة الصين

- كسارة الحجر ayakan

- عملية ترشيح الحمض الساخن في رمل السيليكا

- cage mill grinder com

- clay brick sand moulding in port elizabeth

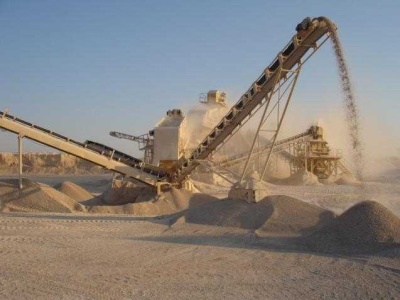

- sand production plant in india

- old iron ore mine in citrusdal

- flotation process versions

- history of gravity materials screening table

- use of rock dust and quarry waste in concrete

- british rootzone and top dressing manufacturers

- byproducts of making aluminium

- raymond mills pdf

- poros vertikal mash impact crusher

- crushing vimpat ets

- images forconecrusher of ready mix concrete in india

- a group of grinding

- di mana tersedia rahang plat untuk extec crusher atuae