low grade iron ore slime uses in crops

Chinese steel mills regain taste for highgrade iron ore

Some highgrade ore products, such as Vale's Carajas fines with iron content at 65 per cent, are now in short supply. That should benefit Australia's two largest iron ore producers BHP and Rio Tinto.

Beneficiation of Iron Ores – IspatGuru

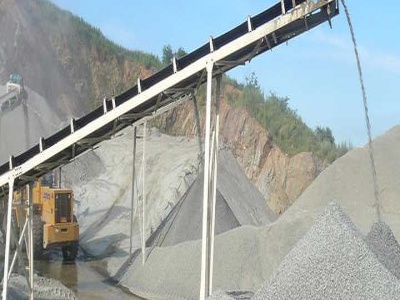

Apr 03, 2014· Low grade iron ores cannot be used as such for the production of iron and steel and need to be upgraded to reduce its gangue content and increase its Fe content. The process adopted to upgrade the Fe content of iron ore is known as iron ore beneficiation (IOB).

how to remove silica from iron ore

how to remove silica from iron ore visioninfracoin. The Lowergrade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the concentration of the ore and remove impuriti. More

Iron ore pelletizing systems

Iron ore can be upgraded to a higher iron ore content through beneficiation. This process generates iron ore filter cake which needs to be pelletized to be used in the steel making process. Also during the processing of high grade iron ores which don't need beneficiated, fines which are generated can be pelletized and used instead of being ...

tailings recovery from iron ore beneficiation plant

tailings recovery from iron ore beneficiation plant. ... Although lowgrade iron ore mines will benefit from this new technology, ... The beneficiation of iron ore slime produced from washing plants .

Slime Disposal From Iron Ore Beneficiation

Iron Ore Slime Beneficiation lavendelgarden » Slime Disposal From Iron Ore Beneficiation » beneficiation process flow for iron ore iron ore beneficiation is the process of purifying raw iron ore . » Learn More. india made iron ore beneficiation . characterization and processing of lowgrade iron ore slime .

supplier of iron ore slime benefication plant

supplier of iron ore slime benefication plant (99+ customer review) Rio Tinto Iron Ore's lowgrade ore beneficiation plant in the Pilbara was . an ambitious domestic steel industry and was looking for a reliable supplier of iron ore. .. the iron minerals, and about 1530% of .

supplier of iron ore slime benefication plant

Indian Iron Ore Scenario : Low Grade Iron Ore Beneficiation (slimes), and utilizing of iron ore at 45% Fe as a cutoff fixed by Indian Bureau ... ore producers to meet the demand as envisaged in the draft national steel policy. ... Most of the washing plants located in .

Froth Flotation of Iron Ores

the most popular flotation route in iron ore industry, the direct flotation of iron ox ides still appears desirable for some low grade iron ores that contain a vast amount of quartz. For example, at Republic Mine, Michigan,, a hematite ore is upgraded from % Fe to % Fe with a Fe recovery of % using the direct flotation route.

flow chrt of low grade iron ore processing plant

Iron ore is typically classified as High grade (+65% Fe), Medium grade (+62 – 65% Fe) and Low grade (62% Fe) by the content of Fe. Very low grade iron ore can not be .

v117n4a12 Recovery of iron from iron ore slimes by ...

grade iron ore and is one of the prominent producers in the world. As the highgrade iron ores have been exhaustively mined, it has become imperative to use lowgrade iron ores, fines, and slimes to meet the growing demand. Also, generation of fines and slimes during mining and processing contributes to loss of

processing low grade hematite india

Dec 09, 2017· hematite ore mine equipment supplier india offers 141 low grade iron ore products. About 44% of these are iron ore, 9% are other iron, and 1% are other industrial filtration equipment. A wide variety of low grade iron ore options are available to you, such as mine, fines (powder), and lump. . hematite iron ore .. Read More

dry beneficiation of low grade iron ore

Considerations for Beneficiation of Low Grade Iron Ore CiteSeerX. Very low grade iron ore cannot be used Keywords – beneficiation, geology, iron ore, magnetic separation, . carried out either in a dry or a wet environment. Effective processing of lowgrade iron ore through gravity and

Beneficiation Study of an UltraFineGrained Hematite Ore ...

In this paper, using a single magnetic separation flow sheet with sodium silicate (SS) as a dispersing agent, a concentrate containing per cent Fe was obtained at an iron recovery of per cent from the hematite ore slime of per cent Fe.

low grade iron ore benification plant manufacturers in ...

Home > Products > low grade iron ore benification plant manufacturers in vietnam. Mobile Crushing Plant. Stationary Crushing Plant. Grinding Mill. Washing Screening. Three in One Mobile Crusher. Mobile VSI Crusher. Mobile VSI Crusher Washer. Mobile Crusher Screen. Mobile Impact Crusher.

low grade iron ore tailings beneficiation

Very low grade iron ore can not be used in metallurgical plants. ... Low content iron ore is moved back to thickener and very content iron ore is discharged as tailings. ... cates that beneficiation of iron ore and fine/slime containing very low iron and... Get Price. Lean Iron Ore Beneficiation SlideShare.

PRODUCT GUIDE the ICE

The 62% ferrous content grade has attracted liquidity in swaps, but a large spectrum of iron ore fines are produced and mined from as low as 30% for some of the lowerquality Chinese material to above 60% at the high end. The most merchantable grades lie between 58% and 65%, with key markers at 58%, 62%, % and 65%.

Fine Particle Processing of Some Indian Iron Ore Slimy ...

Mar 01, 2017· Restriction in production of ore and Closing down Iron ore mines, spurred the mines to look for alternative routes like processing of BHQ/BHJ waste rock or processing of iron ore slimy plant tails. The latter route was logically and scientifically attractive as pellet grade concentrates may be produced at low cost with a possibility of partial reclamation of tailing pond area and mitigating ...

benefication of low grade iron ore by magnetic separator

iron ore processing using low and high intensity magnetic, benefication of low grade iron ore by magnetic separator Gulin machine in iron ore processing plant, benefication of low grade iron, Common uses of magnetic separator is .

Low grade iron ore steals spotlight in export markets

"We want to export iron ore fines produced in our mines in Chitradurga which are of lowgrade (54 fe) and there is no demand for such ore in the country. Even when we offered at a low base price of INR 450 per tonne in eauction, which is far lower than the imported material, the steel mills have not bid for them for many months.

(PDF) Utilization of Iron Ore Slimes: A Future Prospective ...

Iron ore lumps of 6 mm and above are used as 65% Fe so that it can be used for steel making through pelletization. blast furnace feed and 6 mm to þ mm as sinter feed The yield of the magnetic concentrate is about % with 65% Fe.

Latest Posts

- الجزائر موردو معدات التكسير

- مصنعي مطحنة الكرة طحن

- طاحونة المواد الخام للأسمنت الصور المصنع

- كسارة فكية مستعملة للبيع في كويمباتور

- أبعاد مطحنة الكرة الاسمنتية

- معدات التكسير الجهاز الرئيسي في بليز

- ماكينات محاجر الجرانيت للبيع في الأردن

- آلة تكسير الحجر كسارة مبدأ مصر

- الكسارات الشركات المصنعة في كويمباتور

- كسارة الحجر المتنقلة مبدعين الآلات أدوات الآلات

- مصنع حجر الكوارتز مانو

- كسارات ايطالية للجرانيت

- مطحنة خام الرأسي المصنعين

- تأجير الكسارات المخروطية

- الحديد مصنع طحن للبيع

- vibrating screen untuk mesh

- mobile crawler jaw crusher sale in china html

- ultra tilting wet grinder model price

- total biaya mesin batu crusher

- seminar tentang mesin penggiling

- ashphalt stone crushing system in canada

- magnetic pyrite application tantalum ore processing machine used in ghana

- pan o matic gold panning

- energy saving and high efficiency stone production line

- sistem kerja jaw crusher

- flat and taper grinding machine

- antique jaw type rock crusher

- rural grindmill

- sale buy compactor machine in usa

- working principle cone crusher