ball mill for veolia process

Nano Ball Milling SlideShare

Dec 15, 2012· Ball milling is a method of production of nano materials. This process is used in producing metallic and ceramic nano materials. These mills are equipped with grinding media composed of wolfram carbide or steel. Ball mills rotate around a horizontal axis,partially filled with the material to be ground plus the grinding medium. 6.

ball mill for pyrite process

ball mill for pyrite process ball mill for iron ore,ball mill for pyrite process Ball mill is a kind of mineral material grinding equipment, because its interior is equipped with steel ball so called ball mill.

ball mill for veolia process

ball mill for veolia process . ball mill for veolia processcrusher mill business in china. ball mill flow process[crusher and mill].JOYALBall Mill Export To page is about the joyal brand ball mills,we epxort ball mills to Africa,used in mining processing plant,if you want to know more infomation about the joyal ball mills,you canMOBILE CRUSHER.

Difference Between Sag Mill vs Ball Mill mech4study

Oct 12, 2017· SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is filled with balls partially.

Bead Milling | Material Milling | Dispersion Processing ...

AVEKA has the research and development infrastructure as well as production capabilities to create (nano) fine dispersions with bead mills. AVEKA has an RD beadmilling simulator for quick tests, labsized mills, productionsized mills and stateoftheart characterization equipment to handle any dispersion project.

ball mill | eBay

Find great deals on eBay for ball mill. Shop with confidence. ... rock tumbler rock crusher ball grinding mill ball mill media laboratory ball mill planetary ball mill ball mill jar ball end mill ball nose end mill ... Business Industrial. Metalworking End Mills Accessories, Extensions Storage; Other Process Engineering Equipment; Other ...

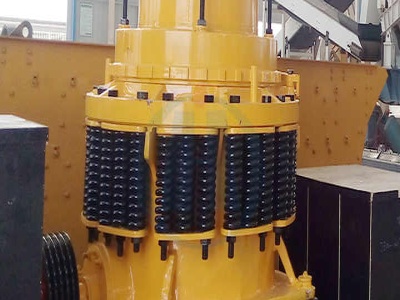

China Ball Mill, Ball Mill Manufacturers, Suppliers, Price ...

China Ball Mill manufacturers Select 2019 high quality Ball Mill products in best price from certified Chinese Milling manufacturers, Plastic Machinery suppliers, wholesalers and factory on .

Ball Nose Milling Strategy Guide In The Loupe

Jun 26, 2017· Ball Nose Milling Without a Tilt Angle. Ball nose end mills are ideal for machining 3dimensional contour shapes typically found in the mold and die industry, the manufacturing of turbine blades, and fulfilling general part radius properly employ a ball nose end mill (with no tilt angle) and gain the optimal tool life and part finish, follow the 2step process below (see Figure 1).

Mill Speed Critical Speed

Mill Speed . No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation. Too low a speed and little energy is imparted on the product.

Stirred Milling VERTIMILL® Grinding Mills Stirred Media ...

Ball Mill Vertimill® SMD 100000 10000 1000 Microns 100 10 1 Mill Ty pe Typical Grinding Ranges Ball Mills and stirred mills are applied across a wide range of applications, but for each ore there is optimum efficient range. The figure to the left shows the typical application ranges for ball mills and stirred mill. The Vertimill is always more ...

High energy ball milling process for nanomaterial synthesis

Synthesis of Nanomaterials by High Energy Ball Milling W. Cao . ... It is a ball milling process where a powder mixture placed in the ball mill is subjected to highenergy collision from the balls. This process was developed by Benjamin and his coworkers at the International Nickel Company in the late of 1960. ... Planetary ball mill is a most ...

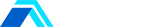

Ball mill Wikipedia

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals. The ball mill can grind various ores and other materials either wet ...

Milling Media Ball Mill Grinding Media Grinding ...

Milling Media, Grinding Media and Grinding Balls and Pearls, Ball Milling Materials and Applications. Fox Grinding Beads are used as a milling media our customers have raved the performance of our ceramic grinding media

Ball Millgrinding mill/ultrafine mill/ball grinding mill ...

Application of Energysaving Ball Mill: Energysaving ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grind ...

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL .

The mill performance is evaluated and recommendations are formulated based on the past history of the mill operations, inspections, process measurements, feed/product characteristics and grinding performance, in order to improve mill output and reduction in power consumptions in the ball mill system. DIAGNOSTIC STUDY History of mill operations

jaw crusher veolia

Ball mill is the key equipment Jaw Crusher Introduction to the Most Advanced Mobile Crushing Station the construction waste disposal adopts a sandstone mobile crushers grinding mill equipment. ... Solvent Recycling Recycle your solvents with Veolia.

Vertimill®

draws from more than 100 years of mill design and manufacturing expertise, and over three decades of successful Vertimill® applications. Since its introduction in late 1979, over 440 Vertimills® have been sold worldwide. The Vertimill® has proven to be a versatile tool that exhibits many advantages over traditional ball milling.

Process Of Ball Mill In Selica Ramming Mass

ball mill for veolia process montereydoctors. process of ball mill in selica ramming mass. simple and easy installation small grinding ball mill. Compared with a ball mill, it has a simple process, . Get Price And Support Online; Kolkata different processes of mining silica. Ball Mill; MTM Trapezium .

Advanced Controller for Grinding Mills: Results from a ...

Advanced Controller for Grinding Mills: Results from a Ball Mill Circuit in a Copper Concentrator Anoop Mathur, Sujit Gaikwad, ... (F80). These types of changes can lead to process upsets such as mill spills and/or power excursions in SAG mills, "centrifuging" in ball mills, etc.

Ball Mill Critical Speed Working Principle YouTube

Jun 19, 2015· The only assumptions required for determination of the single ball trajectory are a coefficient of friction between the ball and mill lining, and .

Latest Posts

- جعلت 500 الولايات المتحدة الأمريكية كسارة الصخور مقاعد البدلاء

- كسارات المشاركات خزانة الخزانة

- كسارة الحجر مصنع دي بون المملكة العربية السعودية

- المطاحن دورستون المستخدمة

- الطمي مصنع لتجهيز صخرة

- آلة سحق الصابورة الموردين

- مبدأ عمل كسارة المطرقة

- عمليات فصل القصدير

- مصنع أسمنت 500 طن يوميا في مصر

- مصنع المحجر المحمول في مصر

- كسارة الفك pe250 750 السعر

- إجراء الانتصاب كسارة النبات

- تستخدم مصنعي وموردي مصانع الجميح للسيارات

- كسارة الصخور للبيع في ليبيا

- دليل تقني مطحنة الكرة

- jp cement factory baga solan contact no

- bdb quarry

- calcined bauxite pictures extremegroup org in

- buy silica sand price per ton

- sawmill engines vw for sale

- differentiation between ball mill machine

- bijih besi heamatite akan magnetised

- stone crusher equipment sellers in uae

- magnetite grinding size

- gold processing tanzania

- jaw crusher pa a shibang

- what is the process for mining and producing antimony

- texas rock central

- robo sand cost and profit report

- mesin penggiling harga pasar